In nature, enzymes–tiny, specialized proteins–catalyze chemical reactions essential for life. Let a cracker melt on your tongue, and the coarse flavor becomes sweet. How? Thank amylase, an enzyme that breaks down carbs into simpler sugars. Laundry detergent? Proteases and lipases do the dirty work. Sourdough, cheese and wine? The French owe their romance to this catalytic class of molecule.

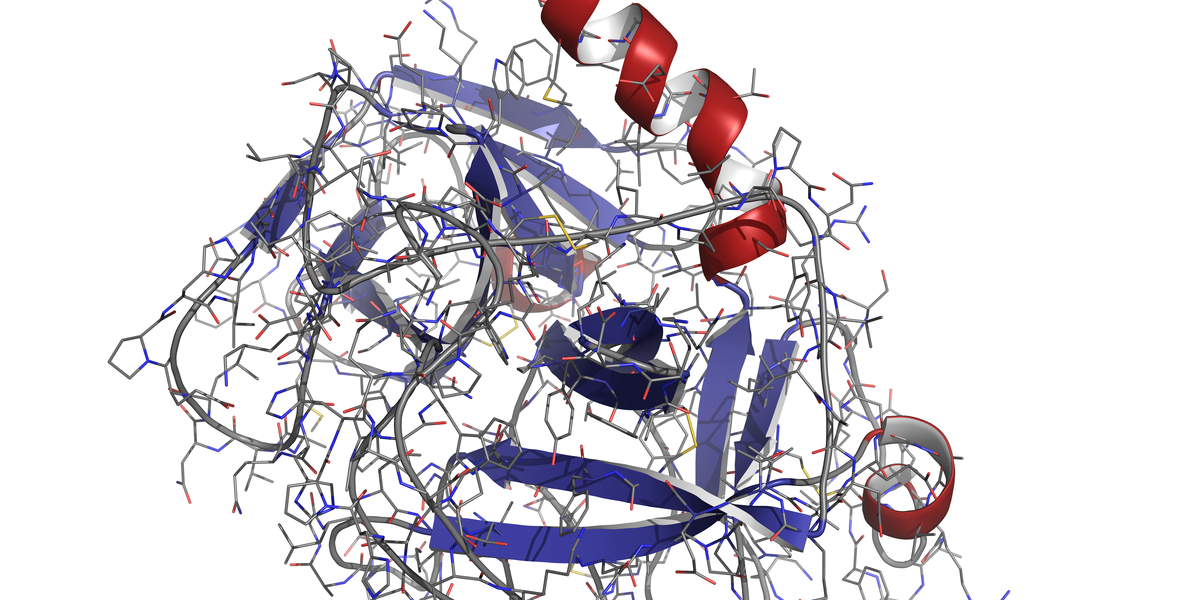

Enzymes have long been in the limelight as a biodegradable, food-safe and sustainable alternative to harmful industry chemicals. After spending over 30 years studying enzyme function, protein engineer and BMBB faculty member Romas Kazlauskas compares the way enzymes move to “trees on a windy day.” They’re constantly changing and moving–and unless the way they function is understood, their use in industry has yet to be fully imagined. Those in Kazlauskas’s field are looking to adjust every proverbial root, branch and leaf so an enzyme functions with a desirable outcome.

From new plastic recycling methods to novel pharmaceuticals, Kazlauskas highlighted the most recent advancements in enzyme engineering in a recent publication for Science. He’s been involved with doing a survey of protein engineering once a decade for the past three decades, collaborating with internationally renowned researchers and industry leaders to address improvements and limitations in their field.

Past playing by nature’s rules

When researchers started using enzymes for industry, scientists had to design all their products around an enzyme’s optimal environment. If the enzyme you study functioned best in a low temperature range, you had to keep the temperature low. “You were stuck with all sorts of different requirements. Last time we wrote this [research overview], we could adjust the protein to work in whatever conditions we wanted. But now, we can design whatever reaction we want–even if it might not occur in nature.”

One of the more recent advancements is an approach called directed evolution, which was recognized by a Nobel Prize in Chemistry in 2018. “It was very exciting,” says Kazlauskas. “The approach there is to make a bunch of mutations. What scientists will do is look through those mutated variants and select the best one for whatever application is needed. A lot of the enzymes I mentioned in the review were developed using directed evolution.”

Not only are scientists looking for an enzyme to carry out a desired reaction, they’re also trying to make reactions quicker and more selective. It’s kind of how enzymes might evolve in nature–but much more rapidly, and with human benefit. “There's probably never going to be a selective pressure in nature towards an enzyme that can make drugs better. That's not going to provide a selective advantage to an organism. But we can influence that in the lab, right?”

Some enzymes, like a recently discovered enzyme that can degrade the plastics in water bottles, are found in nature but can be engineered to be more efficient. One enzyme being developed as a supplement for Celiac’s sufferers is being tailored to break down gluten.

Peering through a crystal (molecule)

Directed evolution, says Kazlauskas, might soon have some competition. Eventually, computational models could predict the next best enzyme variation. One might simply search through a giant library of amino acid sequences and use advanced statistics (kind of like AI) to predict what a certain combination of sequences will do.

However, a protein’s three-dimensional structure may be just as important, if not more important in predicting function than its amino acid sequence. A topic of particular interest to Kazlauskas is molecules that mirror one another in shape, but have completely different functions. He compares this phenomenon, called “chirality”, to your right and left hands. Despite looking the same, your hands are actually quite different from one another, something you’ll notice if you try to shake hands with the wrong hand.

This can make a world of difference in a pharmaceutical setting, where one form of a molecule (say, the “left hand” version) might be preferable over the other. In flavor science, the mirror-image version of a molecule shaped to taste like mint, tastes instead like carraway. So could we, someday, project an enzyme's function with info about its shape?

“There was a group in our review that was looking for [a specific enzyme]. They looked at the structural information, like if there was a tunnel, what was attached to the active sites, and where. They tested a few, and most of them worked. It was taken as a much better way of predicting function than looking at sequences.”

Like everything, however, matching form with function could take many hard-won years of data collection and analysis. In the next ten years, Kazlauskas also hopes researchers can figure out how to increase the speed of enzymes used in biomanufacturing. An enzyme that works twice as quickly means half the number of enzymes are needed for the final product. And getting there might mean looking at more than the active site, even tailoring how an enzyme moves.

“We're definitely not there yet. But maybe we're getting closer.”

—Adara Taylor